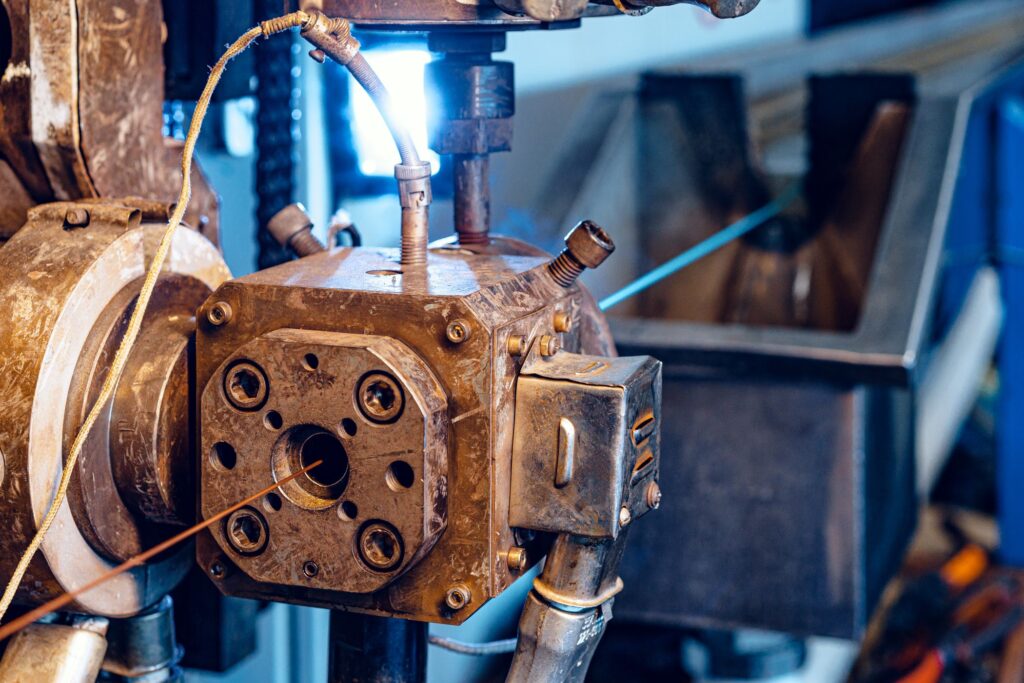

Drag chains, also known as cable chains, are used to guide and protect sensitive cables, hoses, and hydraulic lines. These flexible hollow structures prevent hoses and cables from becoming tangled or damaged when machines are in motion, helping to prevent accidents and unnecessary downtime.

Common Materials

Cable chains can be manufactured using either plastic or steel. Both of these materials offer unique advantages, but that doesn’t mean they can be used interchangeably. Steel offers both high tensile strength and excellent temperature resistance, which makes it ideal for heavy use. The most common types of steel used in cable chains include:

- Stainless steel

- Zinc-plated steel

- Hybrid steel

Plastic cable chains weren’t invented until the early 1970s, but today, they’re nearly as common as steel ones. That said, steel is always the better material for harsh environments and heavy use. Plastic cable chains are best reserved for specialized purposes such as manufacturing sensitive electronic devices that require extremely clean environments.

Design Classifications

Cable chains can be classified by functional design, with linear cable chains moving in a straight line, while circular ones move in arcs. They can also be classified by application.

Standard cable chains have simple designs to facilitate a quick installation. Advanced cable chains offer more separation options and chain widths than standard ones. Extreme cable chains are designed for use in harsh environments and are always made from some kind of steel.

It’s important to take note of these differences. Since every drag chain has a slightly different design, they won’t all be acceptable for every application. When in doubt, ask an expert for advice before choosing a cable chain design.

Drag Chain Applications

Cable chains can be found in many industries and environments, although they are most common in the gas and oil industries. They’re often used in:

- Pipe handling and racking systems

- Multi-purpose and gantry cranes

- BOP handling equipment

- Top drive systems

- Catwalk systems

Cable chains are also commonly found in ports, where they facilitate the operation of large port cranes, vehicle transporters, and in washing systems. Machine tools and green energy systems may also make use of cable chains.

Drag Chain Variants

Cable chains are sometimes used for very specific applications. When this is the case, it’s important to purchase the right style and size. Common drag chain variants include:

- Open or closed

- Steel and stainless steel

- Low noise

- Minimal wear for cleanroom compliance

- Multi-axis movement

- High load resistant

- Temperature resistant

- Water-resistant

- Chemical resistant

- Heavy duty

All heavy-duty cable chains are made from steel. These more durable cable chains are designed to take hard wear, which is important in the oil and gas industry, especially. The nature of the cabling and hoses protected by cable chains necessitate heavy-duty options.

Find a Reputable Supplier

Because cable chains are often used in challenging environments or to protect essential hydraulic, water, chemical, or fluid lines, it’s important to find a reputable supplier. Look for a company that has been in business for at least a few years and has worked with similar clients in the past.